Digital Advancements for More Efficient Operations

Enhanced Control Capabilities ▸

Smarter, safer, and more efficient operations with StimCommander™

Across our fleet, we’re delivering meaningful efficiencies for our customers through StimCommander™, Liberty’s AI-driven, automated rate and pressure control system. This intelligent software empowers pump operators to seamlessly manage on-site pressure and rate across a variety of fleet designs—optimizing performance with precision and consistency.

By automating critical control functions, StimCommander delivers measurable benefits:

Beyond automation, StimCommander continuously monitors equipment health, reducing maintenance needs and extending the life of Liberty’s assets.

A Powerful Intelligence Ecosystem

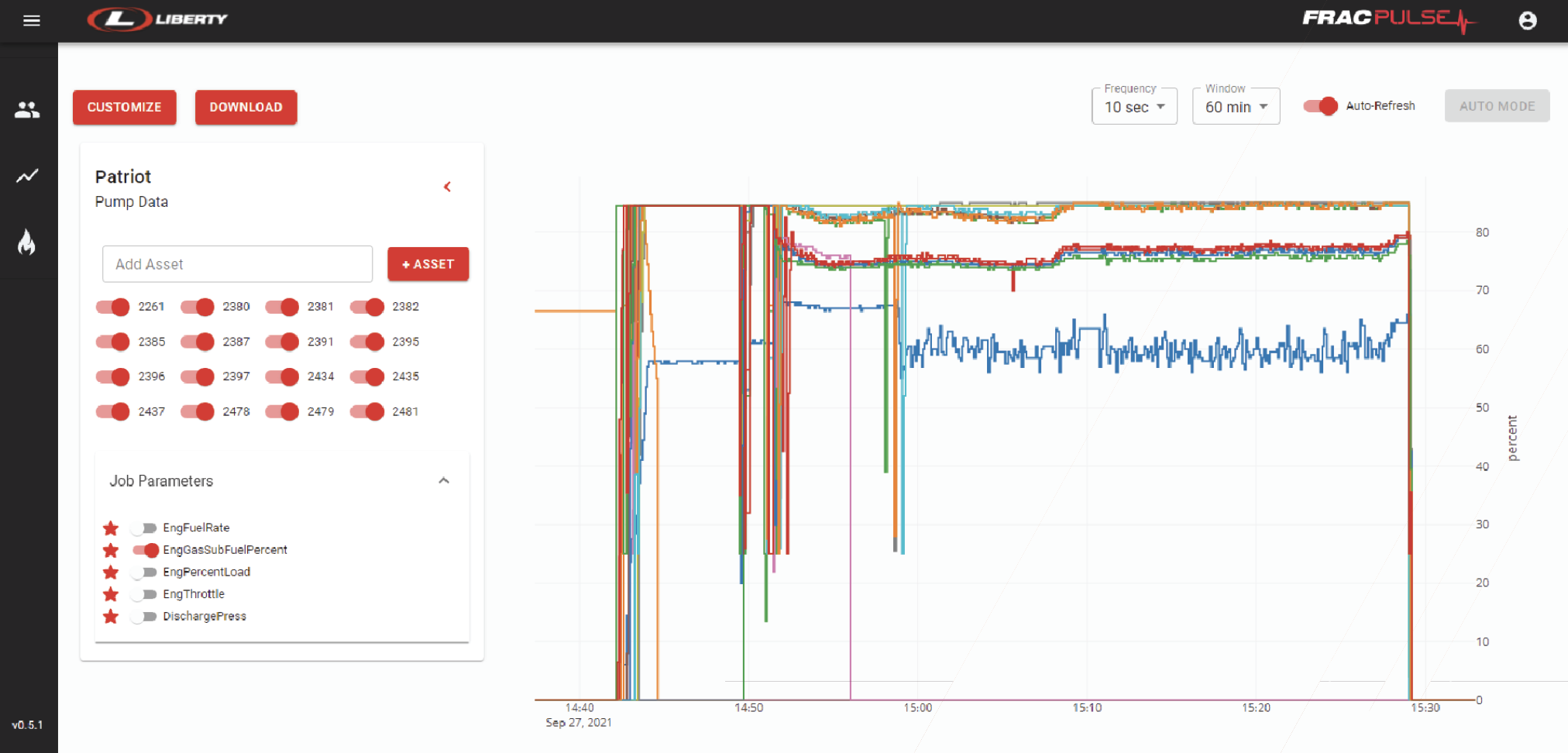

Supporting the StimCommander system is Forge, Liberty’s continuously learning cloud platform. Forge strengthens our AI models by leveraging billions of data points and years of operational experience. Forge integrates insights from other proprietary platforms — like FracPulse, our proprietary, real-time monitoring & data analytics platform — to track the condition, performance, and emissions profile of our fleet.

Together, StimCommander, Forge, and FracPulse form a powerful ecosystem of intelligence and automation—helping Liberty’s operations grow smarter and more efficient.

Proactive Maintenance ▸

Revolutionizing Equipment Maintenance with AI-Driven Insights

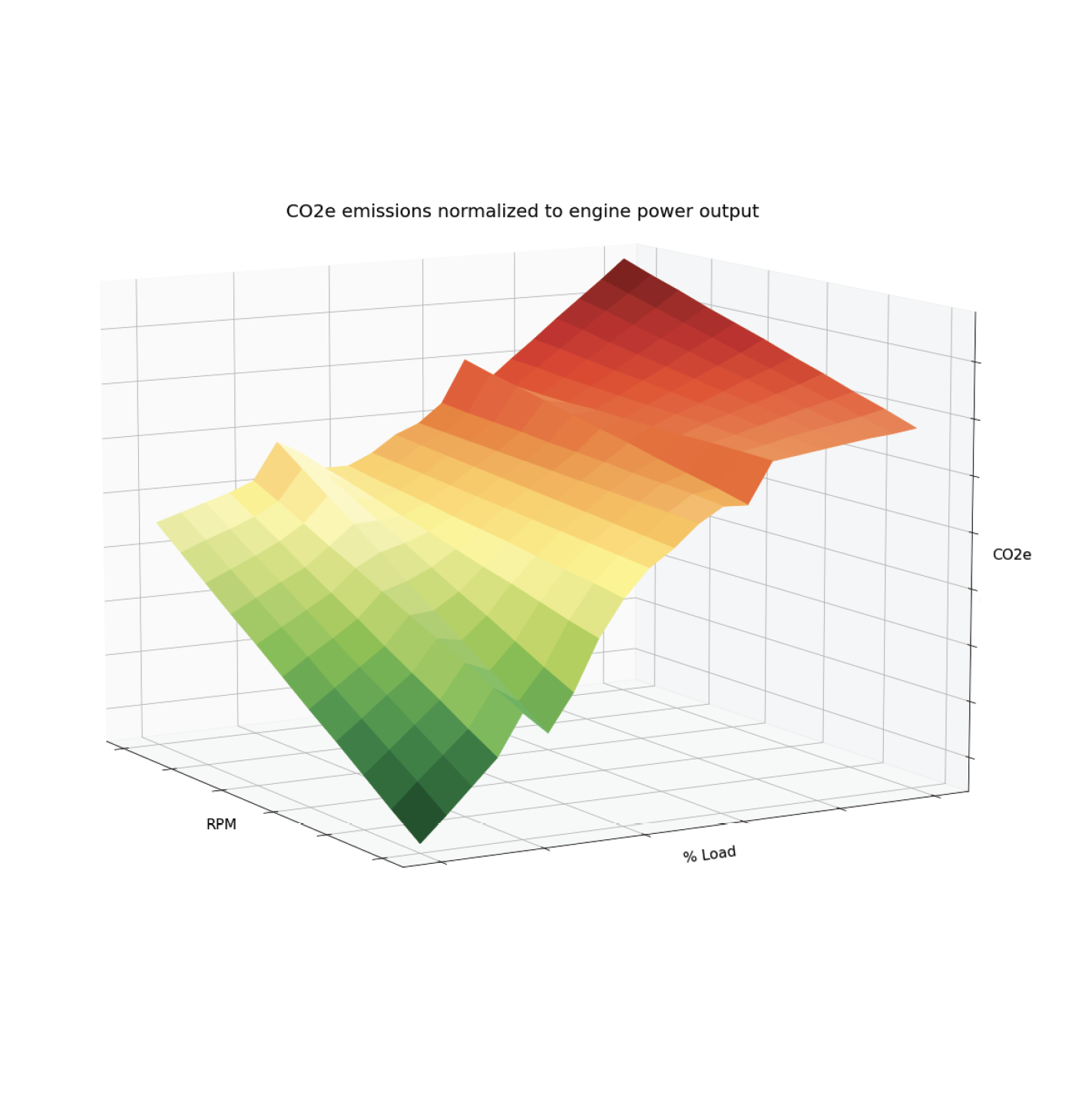

At the core of our innovative approach, FracPulse leverages advanced AI and machine learning algorithms to transform equipment maintenance. Our system leverages real-time data to manage emissions monitoring and reporting, analyzing high-frequency data from diverse sources, including sensors, operational logs, and historical records. This comprehensive data analysis enables FracPulse to detect subtle patterns and anomalies that are beyond human detection. By continuously learning and adapting, our AI models become increasingly precise, providing reliable predictions and actionable insights.

FracPulse is not just about monitoring; it’s about foreseeing. Our predictive maintenance capabilities allow us to anticipate equipment issues before they escalate, significantly reducing downtime and maintenance costs. This proactive approach is empowered by our sophisticated AI models that analyze high-resolution data to quantify wear and tear in its early stages. Liberty is actively implementing these advanced features across our fleet, using FracPulse as a platform to streamline information and quickly adopt new technology.

Real-time Emissions Reporting

Liberty’s FracPulse™ technology utilizes cloud-based infrastructure to monitor over 500 million data points each day from our equipment, allowing us to provide accurate emissions and fuel reporting. This data is used to ensure that we are producing the lowest possible emissions at the highest operational efficiency for each individual job.