Powering Our Next-Gen Equipment Technologies

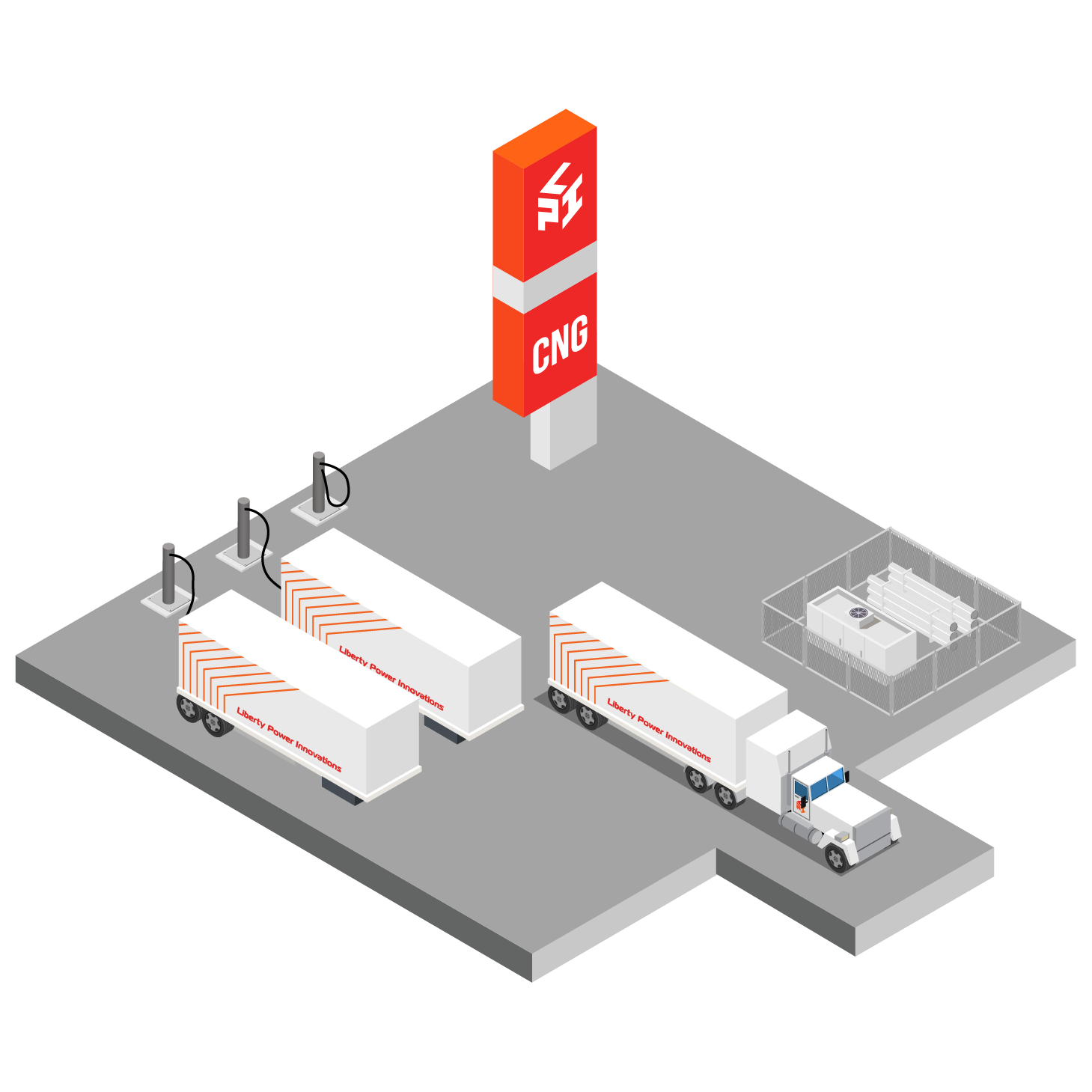

CNG Delivery & Logistics ▸

Integrated Alternative Fuel and Power Solutions for Remote Applications

The oilfield is undergoing a generational technology shift in fuel use from diesel to clean-burning natural gas, with Liberty at the forefront of this change. Liberty Power Innovations (LPI) bolsters Liberty’s technology transition by vertically integrating fueling and power services with compressed natural gas (CNG) supply, and well-site fueling and logistics.

LPI’s on-site fuel distribution service reliably distributes natural gas to pumps and gensets in concert with all sources of natural gas fuel supply.

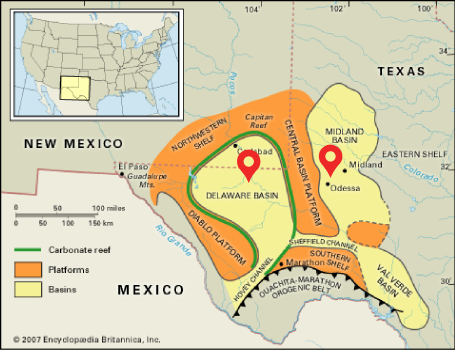

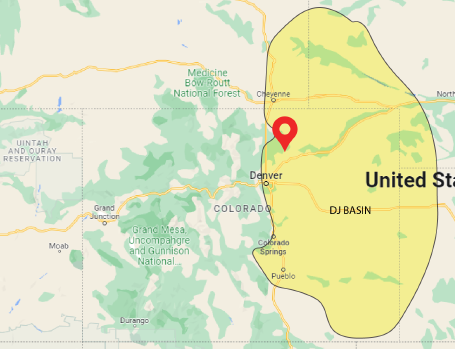

Compression & Delivery Map

Liberty Power Innovations provides dependable local access to CNG, the critical fuel source powering our higher-efficiency, next-generation equipment.

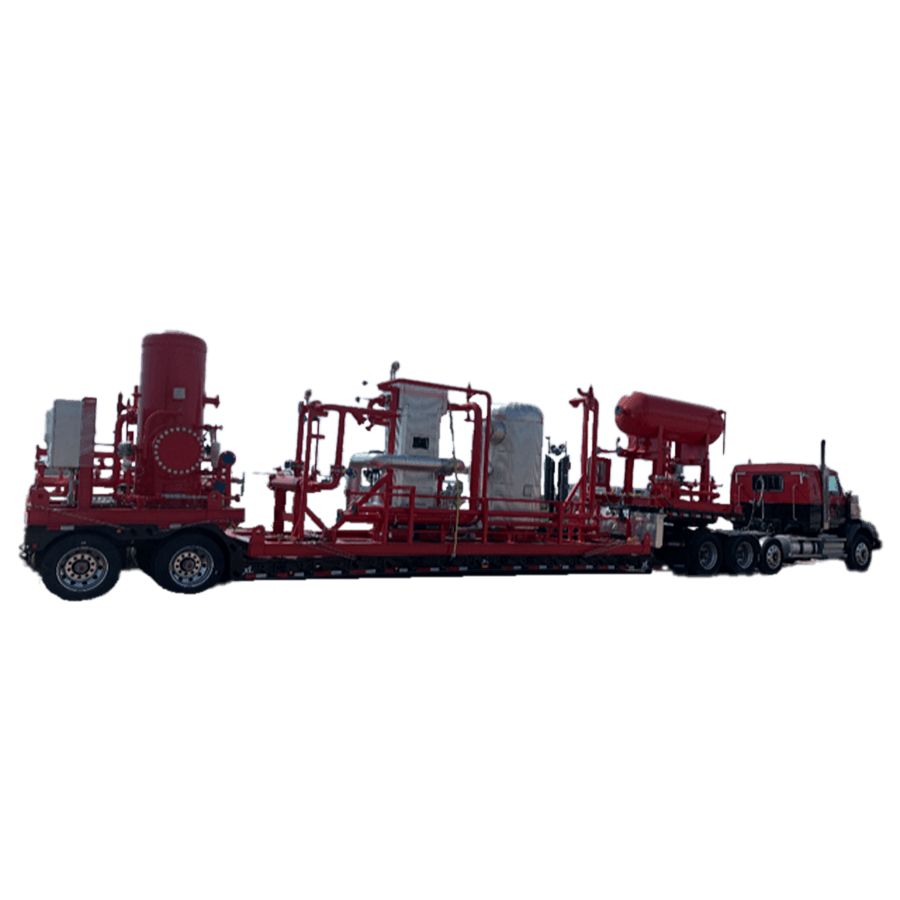

Field Gas Processing ▸

OPTIMIZE AVAILABLE FUEL SUPPLY & RECOVER VALUABLE NGLS

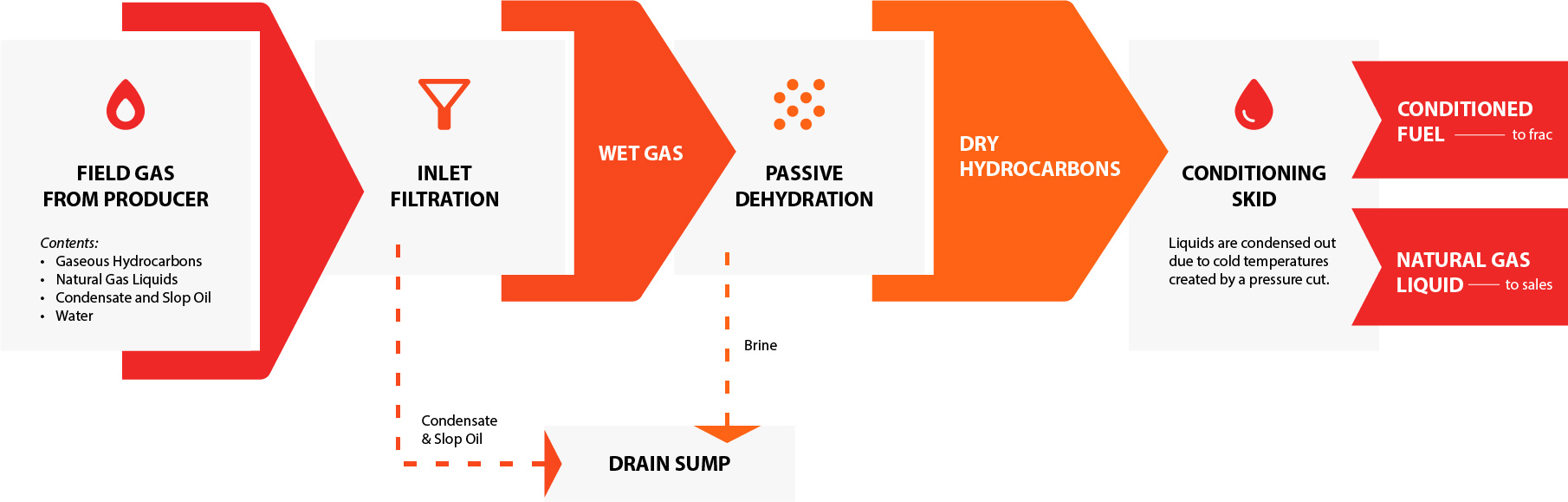

Liberty Power Innovations’ mobile field gas processing units are designed for growing next-generation higher gas rate applications. They can be seamlessly combined with CNG gas to enhance reliability and optimize performance for a variety of natural gas-fueled rigs and frac fleets. Built to handle substantial flow rates of 5,000 MCFD or more, the units provide flexibility for 100% gas and dual fuel operational needs.

LPI’s processing equipment consistently produces a quality fuel stream and a sellable Natural Gas Liquids (NGL) product stream, making it a valuable asset for resource management. It incorporates well-established technology, ensuring reliability and ease of use. Our closed-loop system eliminates the need for on-site flaring of waste streams, thereby reducing overall site emissions.

Field Gas

Field gas processing involves receiving gas supply via pipeline or directly from a producing well, which typically contains heavy hydrocarbons. The process employs the Joule-Thomson (JT) effect to cool the gas to a temperature whereby heavy hydrocarbons condense and are separated, creating an NGL product that can be sold. NGLs are removed to make the gas suitable for use in frac pump engines. Field gas may be mixed with Compressed Natural Gas (CNG) to achieve the desired heating value within the optimal range for these engines. This process ensures that fuel gas meets the required specifications for effective use in various applications.

Seamless Pairing with digiTechnologies ▸

Vertically integrating fueling and power services

Liberty’s suite of digiTechnologies utilizes natural gas to remotely generate electricity and power our next-generation frac and wireline services. Owning the natural gas fuel supply for our fleets ensures execution at the highest level and adds another critical component to our vertical integration strategy.